Automating Magnetorquer Manufacturing

Overview

For the University of Waterloo’s Orbital design team, I developed an automated winding mechanism to manufacture magnetorquers - electromagnetic actuators used for satellite attitude control. These devices generate torque by interacting with Earth’s magnetic field, allowing precise orientation control of CubeSats in orbit.

The Challenge

Traditionally, manufacturing magnetorquers involves manually winding hundreds of turns of thin copper wire around a core - a process that could take days and often resulted in inconsistent results. As part of the Attitude Determination and Control Systems (ADCS) sub-team, I was tasked with streamlining this process.

Solution

I designed and built an automated winding mechanism that reduced manufacturing time from days to just a couple of hours. The system consists of:

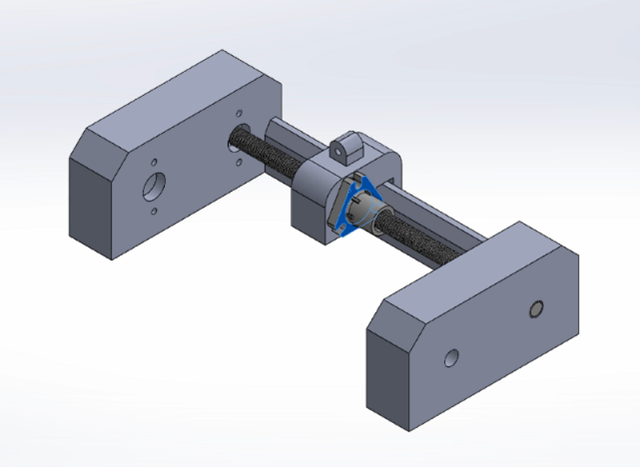

- A Solidworks-designed mechanical frame and winding assembly

- An Arduino-controlled dual BLDC motor system with PID control

- Precision wire guidance mechanisms

- Real-time turn counting and monitoring

Results

The automated system achieved several key improvements:

- Reduced manufacturing time by approximately 90%

- Improved consistency in wire spacing and tension

- Enabled precise turn counting and quality control

- Reduced human error in the manufacturing process

Technical Details

The winding mechanism uses an Arduino to control two BLDC motors, implementing PID control to maintain precise and synchronized rotation speeds. The system includes:

- Dual BLDC motors with closed-loop speed control

- PID controller ensuring synchronized motor speeds

- Automated wire guide to ensure even distribution

- Turn counting system for quality control

- Emergency stop and manual override capabilities

This project showcases how automation can significantly improve manufacturing processes in spacecraft component production, making satellite development more efficient and reliable.